Tool Design Cutting

03:28Tool DesignCutting Tool Design

Nageswara Rao

Posinasetti

January 31, 2008 Nageswara Rao Posinasetti 2

Guidelines for Cutting tool Design

Rigidity

Strength

Weak links

Force limitations

Speed, feed and size

Related force components

Chip disposal

Uneven motions

Chatter

January 31, 2008 Nageswara Rao Posinasetti 3

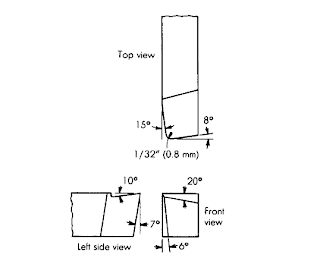

Basic tool angles (Tool Signature)

Back rake angle

Side rake angle

End relief angle

Side relief angle

Selecting carbide Tools

Establish the operating conditions

Select the

–Cemented carbide grade

–Nose radius

–Insert shape

–Insert size

–Insert thickness

–Tool style

–Rake angle

–Shank size

–Chip breaker

Establish the operating

conditions

Feed, speed and depth of cut greatly

influence the machining performance.

Also lead angle affects the

performance

FIGURE F-27 The difference in style A and style D holders for

depth of cut and cutting edge engagement length (copyright ©

General Electric Company).

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

5

January 31, 2008 Nageswara Rao Posinasetti 13

FIGURE F-28 Large, well-formed chips were produced by this

tool with built-in chip breaker (Kennametal, Inc., Latrobe, PA).

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Large depth

of cut

To reduce cutting edge chipping

Increase the speed

Decrease the feed and/or depth of cut

Change to a tougher grade carbide

insert

Use a negative rake

Hone the cutting edge before use

Check the rigidity and tool overhang

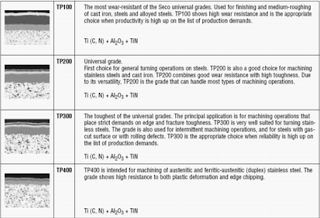

Select the cemented carbide grade

Select the cemented carbide grade

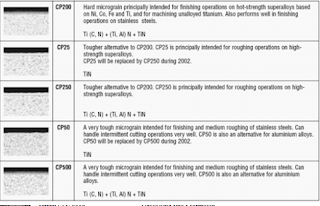

Select the nose radius

Based on surface finish

January 31, 2008 Nageswara Rao Posinasetti 21

FIGURE F-34 Surface finish versus nose radius

(copyright © General Electric Company).

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

8

Select the insert shape

Round – strong and large radius, good

for higher feed rates

Square – medium stronger

Traingular – least stronger, less

number of cutting edges, but more

versatile in use

January 31, 2008 Nageswara Rao Posinasetti 23

FIGURE F-35 Insert shapes for various

applications (Kennametal, Inc., Latrobe, PA)

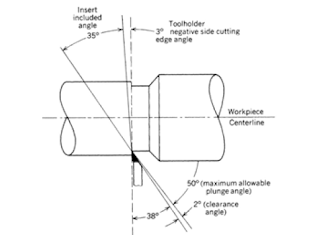

FIGURE F-36 A 38-degree triangular insert used

for a tracing operation (copyright © General Electric

Company).

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Select the insert size

Smallest size based on the depth of cut

used

Cutting edge should be 1.5 times that

of the length of cutting edge

engagement.

10

Select the insert thickness

Gives the strength of the tool

FIGURE F-37 Insert thickness as determined by length of

cutting edge engagement and feed rate (copyright © General

Electric Company).

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

January 31, 2008 Nageswara Rao Posinasetti 30

Select the tool style

Based on the geometry of the

operation to be performed.

11

January 31, 2008 Nageswara Rao Posinasetti 31

FIGURE F-38 Several of the many tool styles available

(Kennametal, Inc., Latrobe, PA).

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

Select the rake angle

January 31, 2008 Nageswara Rao Posinasetti 39

FIGURE F-39 Side view of back rake angles.

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

14

January 31, 2008 Nageswara Rao Posinasetti 40

Select the shank size

January 31, 2008 Nageswara Rao Posinasetti 41

FIGURE F-40 Determining shank size according to depth of

cut, feed rate, and tool overhang (copyright © General Electric

Company).

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

January 31, 2008 Nageswara Rao Posinasetti 42

FIGURE F-41 A boring bar with various

interchangeable adjustable heads (Kennametal, Inc.,

Latrobe, PA).

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

15

Select the chip breaker

FIGURE F-42 Chip breakers used are the adjustable chip deflator

(center) with a straight insert and the type with the built-in chip control

groove.

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

FIGURE F-43(b, c) (a) Negative rake two-sided Kenloc inserts; *Maximum

D.O.C. and feed rates (ipr) are limited by the insert thickness and cutting edge

length. Application ranges are for AISI 1045 steel at 180 to 220 BHN

(Kennametal, Inc., Latrobe, PA.)

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

16

Tool Holder Identification

January 31, 2008 Nageswara Rao Posinasetti 47

FIGURE F-44 ASA tool identification system (Tool Application

Handbook; data courtesy of Kennametal, Inc., Latrobe, PA,

1973.)

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.

January 31, 2008 Nageswara Rao Posinasetti 48

Carbide Insert Identification

17

FIGURE F-45 ASA carbide insert identification (Tool Application

Handbook; data courtesy of Kennametal, Inc., Latrobe, PA, 1973.)

Richard R. Kibbe, John E. Neely,

Roland O. Meyer, and Warren T.

White

Machine Tool Practices, 7e

Copyright ©2002 by Pearson Education, Inc.

Upper Saddle River, New Jersey 07458

All rights reserved.4

Multiple-Point Cutting Tools

Drilling

Reaming

Milling

Gear cutting

Power requirement for Drilling

d = drill diameter, in

f = feed in/rev

Torque, M = 25,200 f 0.8 d1.8

Thrust, T =57,500 f 0.8 d 0.8 + 625 d 2

Power requirement for Reaming

T k f d

d1 = reamer diameter, in.

f = feed in/rev

January 31, 2008 Nageswara Rao Posinasetti 60

Power

Power in HP

M = tool torque, in-lb

N = speed, rpm

Power in Watts = Hp * 746

63,025

P M N c =

21

Machining Power

Depends on the material removal rate

Uses empirical equations developed

based on experiments

See Machinery’s Handbook

– pp 1046 – 1055 (26th Edition)

Pc = power at the cutting tool

Pm = power at the motor

Kp = power constant (see tab 24, 25 and 30)

Q = metal removal rate (tab 29)

January 31, 2008 Nageswara Rao Posinasetti 89

fm = feed rate, in/min or mm/min

f = feed rate for turning, in/rev or mm/rev

January 31, 2008 Nageswara Rao Posinasetti 90

Drilling

31

T = Thrust; lb or N

M = Torque; in-lb or N.m

N = Spindle rpm

32

0 comments